When you consider the rapid evolution of electronics, SMD assembly stands out as a critical component in achieving both precision and efficiency. This technology revolutionizes how components are integrated onto circuit boards, allowing for innovative designs that were once unimaginable. You might wonder how the automation processes, like pick-and-place machines, play a role in this transformation. Understanding these nuances can significantly impact your approach to modern electronics production, especially as new trends continue to emerge in the industry. What’s next for SMD assembly?

What Is SMD Assembly?

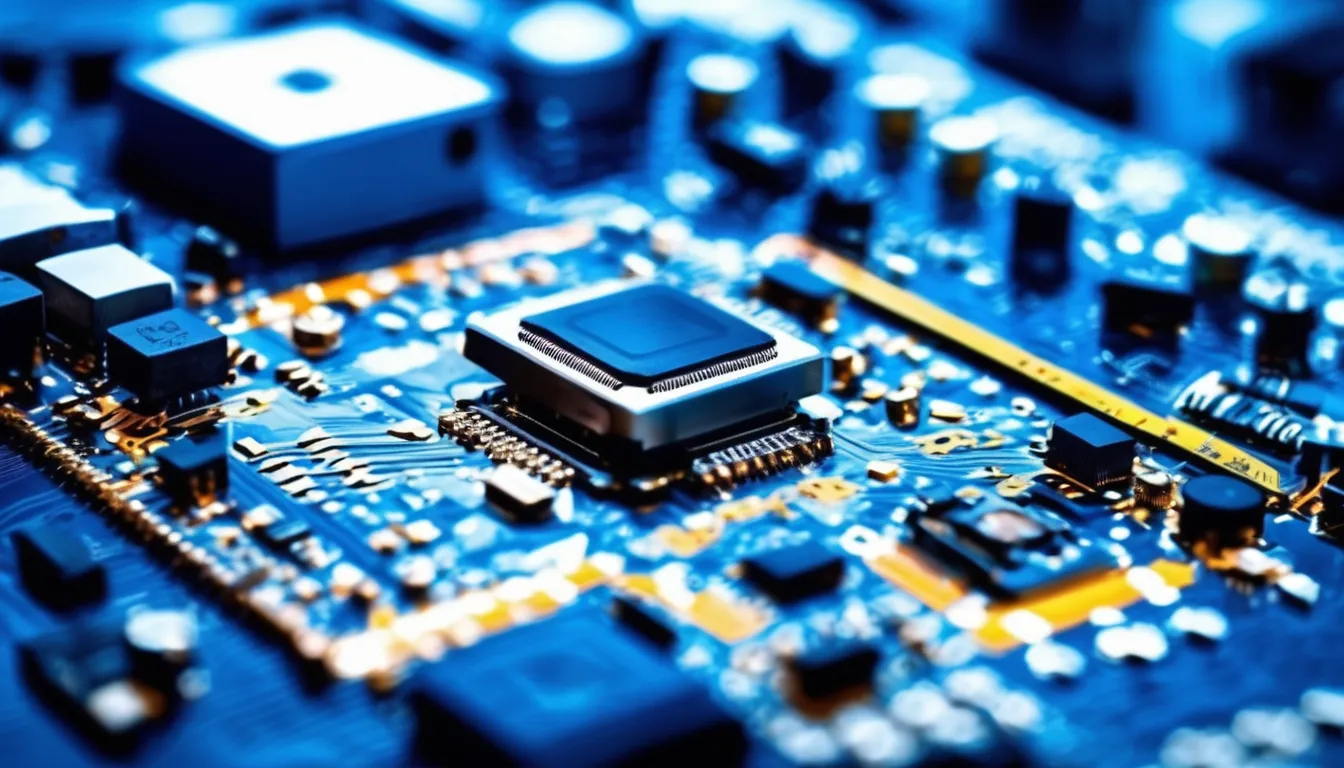

When it comes to modern electronics, SMD assembly plays a crucial role in creating efficient and compact circuit boards. SMD stands for Surface-Mount Device, which refers to a method of mounting electronic components directly onto the surface of a circuit board.

Unlike traditional through-hole technology, where components are inserted into holes and soldered from the opposite side, SMD allows for smaller, lighter, and more densely packed designs.

In SMD assembly, you’ll typically see components like resistors, capacitors, and microchips placed on a board using specialized machines. These machines accurately position each component and apply solder paste to secure them in place.

You’ll notice that this process enables faster production, as automation significantly speeds up the assembly line.

Moreover, SMD assembly supports a variety of component types and sizes, allowing for versatile design options. This flexibility means you can create more sophisticated electronic devices tailored to specific needs.

Ultimately, understanding SMD assembly provides insight into how modern electronics achieve their functionality and compactness, paving the way for innovations across industries.

Benefits of SMD Technology

One of the standout advantages of SMD technology is its ability to save space on circuit boards. By using smaller components, you can fit more functionality into a compact area, which is crucial for today’s miniaturized devices.

This space-saving capability not only leads to lighter products but also helps reduce the overall size of your electronics, making them more portable.

Another significant benefit is the improved performance and reliability of SMD components. These parts often have shorter lead lengths, which minimizes resistance and enhances signal integrity.

You’ll notice that devices using SMD technology tend to operate more efficiently, with less heat generation compared to traditional through-hole components.

Additionally, SMD technology supports higher density assembly, allowing you to increase production efficiency.

With the right equipment, you can automate the assembly process, reducing labor costs and minimizing human error.

This level of automation often leads to faster turnaround times, enabling you to bring products to market more quickly.

SMD Assembly Process Overview

Typically, the SMD assembly process involves several key steps that ensure precision and efficiency in producing high-quality electronic circuits.

You’ll find that each stage plays a crucial role in achieving the desired performance and reliability of the final product.

Here’s a quick overview of the essential steps:

- Design and Prototyping: It all starts with designing the circuit and creating prototypes to test functionality. This phase helps you identify potential issues early on.

- Solder Paste Application: You apply solder paste to the printed circuit board (PCB) using a stencil. This paste will later help connect the SMD components to the PCB.

- Component Placement: Using pick-and-place machines, you place surface-mount components onto the PCB. This step requires precision to ensure proper alignment.

- Reflow Soldering: Finally, you heat the board in a reflow oven, melting the solder paste to create strong electrical connections.

This step solidifies the components in place for durability.

Automation in SMD Assembly

Automation has revolutionized SMD assembly, significantly enhancing both speed and accuracy in the manufacturing process. With the rise of automated pick-and-place machines, you can expect quicker component placement, reducing the chances of human error. These machines use advanced vision systems to identify and position components with pinpoint precision, ensuring that every part is perfectly aligned on the circuit board.

Additionally, automated soldering processes, like reflow and wave soldering, streamline the assembly workflow. They provide consistent quality, leading to fewer defects and rework. You’ll notice that these automated systems can handle a variety of components and board designs, making them versatile for your production needs.

Moreover, integrating automation into your SMD assembly line allows for real-time monitoring and data collection. You can track performance metrics, identify bottlenecks, and make informed decisions to optimize your processes.

As you embrace automation, you’ll also find that it frees up your skilled workers for more complex tasks, enhancing overall productivity.

Future Trends in SMD Production

As automation continues to transform SMD assembly, new trends are emerging that will shape the future of production.

You’ll want to keep an eye on these developments to stay ahead in the competitive electronics market.

- Increased Use of AI: Artificial intelligence will enhance decision-making processes in production, optimizing workflow and reducing errors.

- Sustainability Practices: Eco-friendly materials and energy-efficient machines will gain traction, aligning with global sustainability goals.

- Flexible Manufacturing Systems: You’ll see a shift toward adaptable production lines that can quickly switch between different products, increasing efficiency.

- Advanced Inspection Technologies: Automated optical inspection systems with machine learning capabilities will ensure higher quality control, catching defects earlier in the process.

Conclusion

In conclusion, SMD assembly is revolutionizing the Leiterplattenbestückung industry with its precision and efficiency. By embracing this technology, you can enhance your product designs, reduce costs, and improve reliability. The automated processes streamline production, allowing you to meet the growing demands of the market. As trends continue to evolve, staying updated on SMD advancements will keep you competitive in this fast-paced environment. Don’t miss out on the benefits that SMD assembly can bring to your projects!